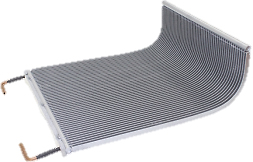

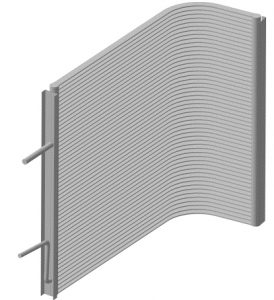

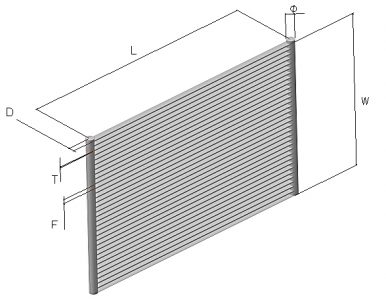

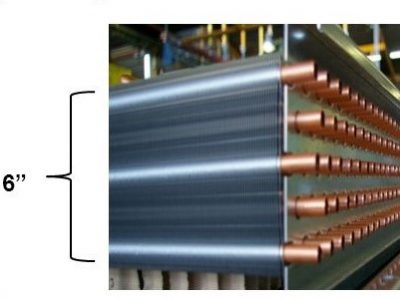

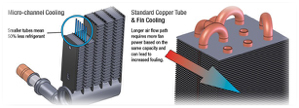

- We design and manufacture micro-channel fin and tube heat exchangers based on client requirements, suitable for any cooling system.

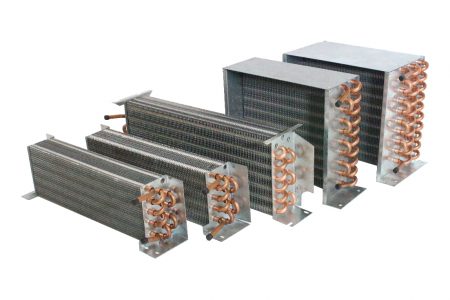

- We design and replace a wide range of heat exchangers.

Applications:

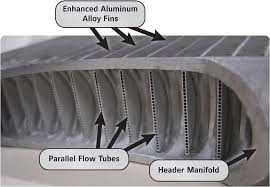

We design and manufacture micro-channel condensers suitable for Industrial uses.

Applications:

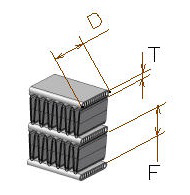

Tubes:

Fins:

Applications:

Solutions offered:

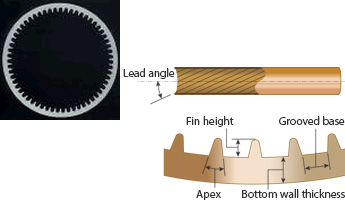

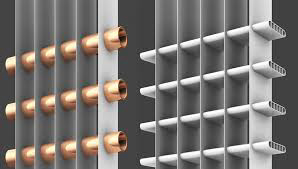

Tubes:

Fins:

Applications:

Solutions offered:

Tubes:

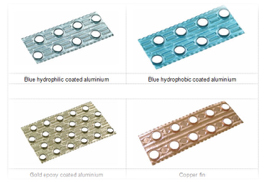

Fins:

Applications:

Casing Material:

Tubes:

Fins:

Applications:

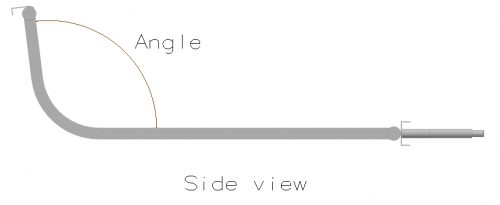

End fittings:

Solutions offered:

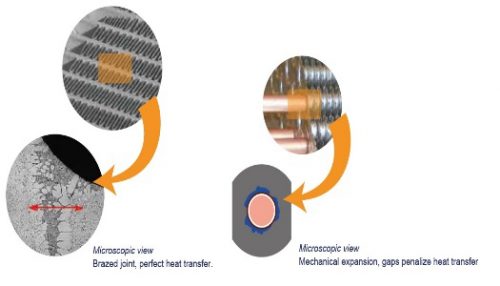

Teriak Group has the ability to design and replace heat exchangers using the latest design software