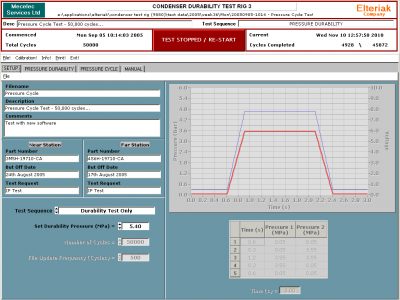

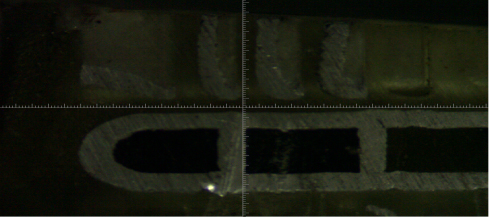

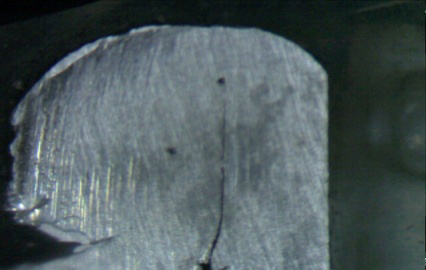

Our labs are equipped with the latest technology to analyze and validate the design and performance of any heat exchanger product.

With 20 design engineers we are capable of designing according to

clients’ standards and specifications with higher performance and efficiency at lower cost.

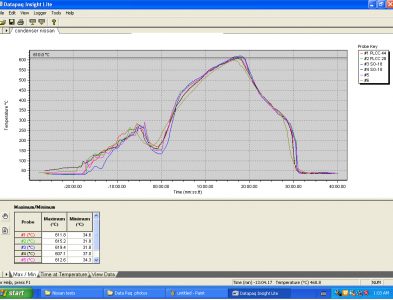

Heat exchanger capacity and performance analysis: (Unilab MCHE,

Unilab professional)